Confused about basement wall insulation? Read on…

The basement is a standard feature in most American homes. However, basements can be one of the most challenging places to work on, partly because of its location. However, basement wall insulation is a must in any home. It provides a solution to problems like cold air leaking in, mold and fungal growth and saves up to 30% of your energy cost.

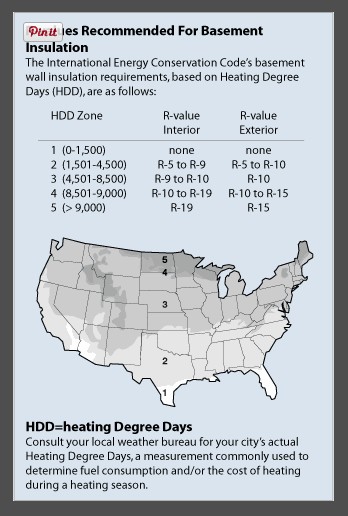

Insulation to the basement wall is done at both sides of newer homes and only on the interior of older houses. When deciding on the best type of insulation, you’ll have to take into account the R-value you’ll need for the basement walls you want to insulate. The R-value is the maximum thermal performance of the insulation when properly installed. Make sure any leaks are sealed off before adding insulation into your basement walls to prevent loss of heat. Also it is a good idea to waterproof seal the concrete or brick walls. When your basement is still unfinished it might be a good idea to add a medium size exhaust fan which will help a lot with air circulation.

Insulating the exterior of the basement walls for new constructions will reduce heat loss through the foundation, provide some protection from moisture, protect the damp-proof coating, make the foundation part of the thermal mass of the conditioned space, reducing temperature swings, reduce condensation on the interior part of the basement walls and conserve room area compared to installing insulation on the interior. However, for many homes that are already built, interior insulation for basement walls are more practical. Interior wall insulation is less expensive, almost any insulation can be used and reduces the threat of invasive insects.

The type of house, the condition of its foundation and the climate plays a big role in determining which insulation is best for you. It’s better to consult your contractor first before picking any.

There are many types of insulation available out there depending on personal preference as well as climate.

1.Blanket insulation

The most common and widely available type of insulation for basement walls is blanket insulation. It comes in the form of batt and rolls. The material consists of flexible fibers like fiberglass. Other types of materials also include mineral wool, plastic fibers and natural fibers. Rolls can be hand cut or trimmed according to your basement wall specification. Blanket insulation usually come with a facing that acts as vapor or air barriers. Certain batts have flame resistant facing for parts that will be left exposed. Fiberglass insulation has a thermal resistance or R-values between R2.9 – R3.8 per inch of thickness. High performance fiberglass blankets have R-values between R3.7 – R4.3 per inch of thickness.

2.Concrete wall insulation

The concrete foundation of your basement also has an R-value which can be increased if the cores of the concrete are filled with insulation. However, this method isn’t very efficient as the heat dissipates through the solid parts of the concrete wall through mortar joint and web blocks. It’s better to insulate over the surface of the concrete either on the exterior or on the interior part of the concrete walls. Insulating on the exterior side has the added advantage of containing the thermal mass within, which helps to moderate indoor temperature. In the United States, two common concrete insulation are autoclaved aerated concrete (AAC) and autoclaved cellular concrete (ACC). Autoclaved concrete has about 80% air by volume, and ten times better insulation compared to conventional concrete. However, it does absorb water easily, so a layer of protection is required. AAC uses high silica sand, while ACC use fly ash, waste ash from burning coal in power plants.

3.Foam board or rigid foam

Foam boards can be used to insulate basement walls effectively. Usually made from polystyrene, polyisocyanurate (polyiso), and polyurethane, it provides good thermal resistance and loss of heat from structural elements like wood and steel studs.

4.Insulating concrete forms

Insulating concrete forms are forms for poured concrete walls. It is a system of interconnected foam boards or interlocking hollow- core foam insulation blocks fastened with plastic ties. Sometimes steel rods are added to reinforce the concrete blocks. It creates high thermal resistance, around R-20. However, insects and ground water easily get into the foam webbing around the concrete-filled cores of the blocks. Manufacturers deal with this by making insecticide treated foam blocks and then waterproofing them.

5.Loose-fill and blown-in insulation

Loose-fill insulation is made of small particles of foam, fiber and other materials. The small particles form insulation between walls that can conform to any shape without disturbing the structure. This type of insulation is suitable for basement walls that are difficult to install other insulation with. The materials used for loose-fill insulation is cellulose which is made from recycled newsprint, fiberglass which contain 20-30 percent recycled glass and mineral wool containing about 75% recycled industrial product. These three materials are blown in by experienced installers. Other lesser known materials are polystyrene beads and vermiculite which are poured in. Vermiculite are seldom used today because they sometimes contain asbestos.

6.Sprayed-foam and Foamed-in-place insulation

Liquid foam is an option for basement wall insulation that can be sprayed, foamed-in-place, injected and poured, creating an effective air barrier. Common types of liquid foams are cementitious, phenolic, polyisocyanurate (polyiso) and polyurethane. Icynene foam is excellent as insulation against air and water, while tripolymer foam has good resistance to fire and water. It can be quite costly compared with other forms of insulation, but it has a higher R-value and creates an air barrier, as well as removing the need for certain cost for caulking or taping joints.